The JOSY Advantage

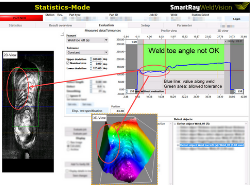

By combining SmartRay’s pre-calibrated 3D sensors with advanced algorithm processing, JOSY’s high-accuracy weld inspection meets international measurement standards.

Sensor performance is essential to the accuracy of a weld inspection system. The JOSY turnkey weld inspection solution relies on SmartRay’s advanced 3D metrology sensor technology. Compact, agile and accurate, JOSY’s sensors are pre-calibrated for reliable, repeatable results, enabling JOSY to be configured in the best way for each application.

100% INLINE INSPECTION • CONTROL QUALITY • REDUCE COSTS • FLEXIBLE & SCALABLE

Your Benefits

ACCURACY

Sensor performance is essential to the accuracy of a weld inspection system. The JOSY turnkey weld inspection solution relies on SmartRay’s advanced 3D metrology sensor technology. Compact, agile and accurate, JOSY’s sensors are pre-calibrated for reliable, repeatable results, enabling JOSY to be configured in the best way for each application.

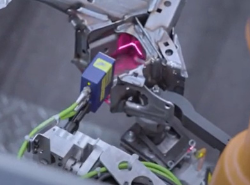

REACHABILITY

As SmartRay’s ECCO 3D metrology sensors are the most compact on the market, JOSY is able to inspect more welds than any other inspection system. JOSY’s highaccuracy sensing enables 100% automated inspection capability for a wide range of parts. This unrivalled reachability speeds up cycle times across multiple inspection processes – ensuring you meet your targets

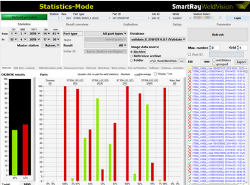

PRODUCTIVITY

JOSY constantly optimises the production process. Staff and system costs required for additional inspection needs are reduced, while increased uptime is supported by identifying preventive maintenance needs.

CERTAINTY

JOSY provides certainty for our customers. Compared to human inspection it gives the same result day after day, year after year, with no fluctuation, no subjectivity.

Why choose automated weld inspection from SmartRay?

Working with you

SmartRay provides a complete turnkey solution to your weld seam inspection application from initial evaluation through to project handover: